- Home

- Knowledge Hub

- Case Studies

- Asset management begins with correct water treatment

Asset management begins with correct water treatment

- Case Studies

- 26 June 2018

- by EUROWATER

Optimum water treatment will i.e. help prolong life cycles of the critical components in a district heating system, including accumulation tanks, boilers, heat exchangers, the piping transmission and distribution network. Furthermore, correct water treatment can bring along both water savings and energy savings.

Definition of Asset Management

Wikipidia gives a good definition of the engineering environment perspective: “The practice of managing assets to achieve the greatest return (particularly useful for productive assets such as plant and equipment), and the process of monitoring and maintaining facilities systems, with the objective of providing the best possible service to users in all dimensions. Infrastructure asset management is the combination of management, financial, economic, engineering, and other practices applied to physical assets with the objective of providing the required level of service in the most cost-effective manner. It includes the management of the entire lifecycle – including design, construction, commissioning, operating, maintaining, repairing, modifying, replacing and decommissioning/disposal—of physical and infrastructure assets”.

Relation between Asset Management and Water Treatment ?

Well, correct water treatment will prevent corrosion and thereby have a positive effect on all issues mentioned above. Optimum water treatment will indeed prolong life cycles of the critical components in a district heating system, including accumulation tanks, boilers, heat exchangers, the piping transmission and distribution network. In short: Extend life cycles of all the expensive components in a district heating system. Furthermore, correct water treatment will have a positive effect on maintenance requirements as well as maintenance costs i.e. for boilers, heat exchangers etc. (including reducing the annual downtime significantly).

Water savings as well as energy savings can also be related to the positive impacts of proper water treatment.

It is quite clear that pipe corrosion (as a result of incorrect water treatment) can cause water leakages – whereby the district heating company loses treated water – and energy – as the water has first been heated, then pumped out in the distribution network.

Intrusion of untreated water often leads to pollution in the network that can further add to problems like corrosion and precipitations. Therefore, such undesired water needs to be treated.

Experience has shown that if water intrusion into the network is not addressed properly then cost impact will be significantly higher due to advanced corrosion and further water leakage. This issue represents a much higher cost compared to addressing the problem correctly by implementing partial stream filtration.

When the district heating company repairs leakages/corroded pipes, this will often cause interruption of supply for its customers. This can also result in lost revenue as well as image issues for the district heating company. Finally, the cost for the repair as well as replacement pipes/joints needs to be included in the cost calculation for incorrect water treatment.

Most of the make-up water lost every year leaks out into nature or enters into installations at the residential buildings. Thus, there are good reasons to keep chemicals in water treatment at an absolute minimum.

A well-maintained plant through proper water chemistry is therefore also a safety issue in the daily operation as well as an economical and environmental gain.

Recommendations on Water Treatment from the Danish District Heating Association

The Danish District Heating Association recommends to minimize (and where possible fully avoid) the use of chemicals – especially for removal of oxygen in the water, where new technologies have been developed.

The Danish District Heating Association recommends to minimize (and where possible fully avoid) the use of chemicals – especially for removal of oxygen in the water, where new technologies have been developed.

Chemicals clearly adds to the salt content in district heating water, resulting in increased conductivity and thereby causing risks for corrosion. Chemicals add to the operational costs (OPEX), while they are also causing a health and safety issue for storage and handling. Finally, it makes sense that a sustainable heating system is operated through use of sustainable components/technologies.

Twentyfive years ago, most Danish district heating companies produced make-up water from municipal tap water by softening to remove hardness in water, then added chemicals for pH-adjustment and oxygen removal.

In addition to softening today, the recommendation calls for removal of salts through membrane technology (RO) or ion exchange technology in order to produce demineralized water with low conductivity.

These steps are then followed by oxygen removal, e.g. through membrane technology (membrane degassing) without the use of chemicals.

The last step is adjustment of pH (9,8 +/- 0,2) by means of sodium hydroxide: The only chemical required.

However, the general picture is that chemicals historically have been added to try to remedy a problem of more fundamental character with inadequate water chemistry. The water treatment recommended by the Danish District Heating Association takes the basic conditions of corrosion into account and tackles the problem without the use of chemicals. This may be considered as a professional way to handle the real issue before it becomes a problem.

Looking back, use of demineralized water and removal of oxygen without chemicals were often not economically feasible – now this has changed due to new technologies available on the market.

On top of that, chemicals are expensive so investments in new technology to remove oxygen without chemicals represent a short return on investment.

As a conclusion, the recommendations from the Danish District Heating Association can be implemented as the modern, correct way to secure optimum water chemistry, and optimize life cycles as well as reduce maintenance costs of the district heating system.

The German water treatment standard for district heating, AGFW FW510, to a large extend shares conclusions with the Danish recommendations. The Danish guidelines, however, are more comprehensive and detailed i.e. concerning recommended pH-range as well as oxygen levels in the water.

Case Story: Aars District Heating Company

Aars District Heating company produces and distributes heat and electricity (own waste-to-energy plant) for a population of 5,500 people in Northern Denmark. Distribution network of approx. 150 km.

Until recently, the company used softened water and conventional chemicals to treat the water (i.e. for oxygen removal) – along with a vacuum degasser.

The management then decided to implement the water treatment recommendations from the Danish District Heating Association and add installation of demineralization (RO unit) and membrane degassing for oxygen removal to the softening process. Due to this investment they are able to reduce consumption of chemicals to a minimum.

The return on investment (ROI) expected to be around five years – however, the five years in fact do not take following positive factors into account:

- The improved life time for the pipe distribution infrastructure etc. – which obviously is another important financial gain.

- Minimized water leakages from the distribution system (due to reduced corrosion).

- Improved energy efficiency (improved heat transmission in heat exchangers etc.).

Case Story: Hvide Sande District Heating Company

Hvide Sande District Heating company is a consumer owned DH company for a town in Western part of Denmark (3,000 inhabitants) – including both production and distribution of heat. Distribution network of approx. 170 km – containing an amount of approx. 4,000 m3 water.

Until recent investment in water treatment the company used softened water and conventional chemicals to treat the water (i.e. for oxygen removal).

The company then decided to follow the water treatment recommendations from the Danish District Heating Association and add RO for demineralization and a membrane degasser for oxygen removal. As a result the use of chemicals almost stopped.

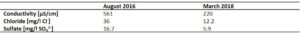

The measurements shown below illustrates the very significant water quality improvements for both make-up water and circuit water in the distribution network. This is clearly benefitting life cycles of critical plant components as well as the pipe system in place. The new water treatment will also help prevent water leakages due to corrosion in the distribution system.

Improvements in make-up water quality measured:

Chemical consumption reduced by more than 90%

Results measured in the distribution network (circuit water):

The positive tendency for the measurements is that the above values keep dropping to a lower and lower level.

Obviously, similar case stories from larger district heating companies also exists. However, the chosen cases serves as inspiration for district heating companies in emerging markets, where systems often are smaller initially.

Source:

EUROWATER is a leading, independent Danish manufacturer of water treatment solutions with 400 employees throughout Europe. The single most important business sector is the district heating/energy industry. The company has manufactured solutions for district heating and energy companies for several decades: Boiler heating plants, combined heat & power plants, waste-to-energy plants as well as solar heating plants. Installations in Denmark, Sweden, Finland, Germany, The Baltic Countries, Norway, Poland, Austria, The Netherlands, Belgium. France, Switzerland, Ukraine etc. – markets with own sales and service teams.

Latest News

-

-

26.10.2021 Celsius Summit 2021 – Energy Democracy

26.10.2021 Celsius Summit 2021 – Energy Democracy