- Home

- News

- District Energy in the News

- Lithuanian District Heating celebrates its 80th anniversary

Lithuanian District Heating celebrates its 80th anniversary

- District Energy in the News

- 07 August 2019

- by Dr. Valdas Lukoševičius - President LDHA

12 June marked the 80th anniversary of the first district heating system launched in Lithuania. It is a great opportunity to look back and review the development of Lithuanian DH sector. To assess achievement and confidence in the new challenges facing the country’s heat economy. To remember where we were 80 years ago and reflect on where we are heading.

The beginning…

District heating (DH) in Lithuania traces its history back to June 1939 when this energy technology was put into service in the largest interwar construction project finished in Lithuania at the time – the building complex of the Vytautas Magnus University Medical Campus (Clinics) in Kaunas, designed by French architect Urbain Cassan together with his colleague Elie Ouchanoff.

Fig. 1 The building complex of the Vytautas Magnus University Medical Campus (Clinics) in Kaunas, Fig. 2 One of the first boilers made by Gebrüder Wagner as well as other heat supply equipment of that time are still standing since the building of the boiler house in 1939

On 12 June 1939, Pranas Drąsutis, the representative of the Energy Committee of the Republic of Lithuania, announced at the meeting of the Construction Commission of the Vytautas Magnus University Clinics that boilers in the newly built boiler-house of the Clinics were tested at the trial load and found ready to supply steam and hot water. The then modern boiler-house had three water-tube drum-type steam boilers with moving grates made by Gebrüder Wagner Dampfkesselfabrik und Feuerungsbau. The boiler-house generated thermal energy for heating , hot domestic water and process steam for laundry, disinfection chambers, kitchen facilities, sterilisers used in operating rooms, etc. The boiler-house and the equipment installed therein, as well as a 75 m brick chimney, were designed by engineer Jonas Jasiukaitis and engineers from German company J.S. Fries Sohn. Construction works were carried out mainly by Lithuanian companies and their employees. Today, one of the first boilers can still be seen in the boiler-house.

Development of district heating

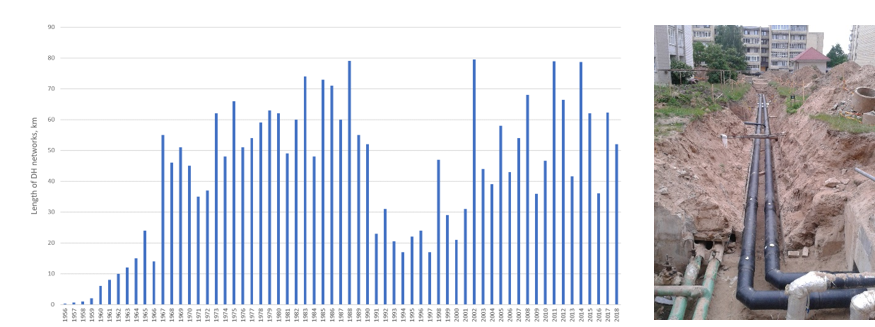

During 80 years, the Lithuanian DH sector faced numerous changes and transformations. Cities and towns destroyed during the World War II were rebuilt and developed mainly from 1960 to 1990. At that time, the development of DH networks was in line with rapid construction of multi-storey buildings. The figure 3 below shows the statistics of DH pipeline works.

Fig. 3 Development of DH networks in Lithuania

Most of the DH systems in Lithuania were installed during the Soviet period, when cities were built in a planned manner and even the smallest towns used district heating and hot water supply. In the times of the planned economy, there was predominance of typical technological solutions, consumers paid on the basis of the set norms, energy was relatively cheap and energy saving was not an issue. After the war, the Lithuanian DH sector mainly used peat, coal and fuel oils for heat production. Later, with the installation of a gas pipeline system, most boiler-houses and power plants started using Russian natural gas, and fuel oils served as the back-up fuel.

After the restoration of independence, Lithuania managed to preserve all of the larger DH systems, but they had to be adapted to new and altered working conditions. Today, the Lithuanian DH sector supplies a relatively high share of heat for consumption compared to other EU countries – more than 50% of total heat consumption. Only Finland, Sweden and Estonia have similar shares of the DH sector. In Lithuania, district heating is supplied to more than 700 thousand apartments. District heating is also supplied to the majority of education and health institutions, other public establishments and commercial buildings.

The Lithuanian district heating sector in the period of independence

After the restoration of Lithuania’s independence and the transition to free market relations, the district heating sector was seen controversially due to the surge in heating prices and poor economic power of consumers. Lithuania was dependent on the sole supplier of natural gas, the Russian concern Gazprom, and the conditions it dictated. The public has realised the need to modernise district heating (DH) systems, to make them more efficient and to adapt them to a different types of fuels. It was quite a unique task, involving the need to incorporate new modern technologies and new business models into the post-Soviet system.

The establishment of the National Regulatory Authority for Energy and its strong and independent status have played an important role in the development of the Lithuanian DH sector. The unified pricing and regulation set at the national level created preconditions for eliminating politicking in the heat sector, fixing reasonable prices and making other unpopular but necessary decisions.

In 1997, building-level inlet heat meters were already in place in all of the buildings served by the Lithuanian DH sector. This allowed measuring the actual consumption of thermal energy and consumers were billed for their actual consumption. Lithuania was one of the first countries in the post-planned economies to introduce heat accounting and recording. Almost 30,000 heat meters have been installed, of which more than 34% have the remote reading system. In large cities, modern remote heat meter reading is predominant; consumers can follow their heat consumption in their households online. The level of energy efficiency in individual buildings determines building prices and motivates investments into energy saving. Measurements have shown that the relative heat consumption (kWh/m²) in different buildings varies up to 10 times, with the difference in heat prices (cents/kWh) in different cities not exceeding two times. Lithuanian heat suppliers and their association (Lithuanian District Heating Association, LDHA) publish detailed monthly statistics on heating costs and their causes and provide consumers with information on saving opportunities.

Another major stage of modernisation which has proven itself was completed in 2004 and involved the replacement of group substations with individual automated heat substations in buildings. This not only saved about 15% of heat, but also significantly reduced pipeline maintenance costs, improved heating regulation and service quality.

Even more rapid modernisation of DH systems started after 2004, when Lithuania joined the European Union and had the opportunity to use the EU aid for the renewal of energy infrastructure. This period was marked by significant new pipeline installation and replacement works, including accelerated renewal of the preserved DH systems with modern pipelines, optimisation of their configuration and temperature regimes, etc. in many Lithuanian cities. This enabled halving heat transfer losses, which means not only fuel saving but also reduced environmental impacts.

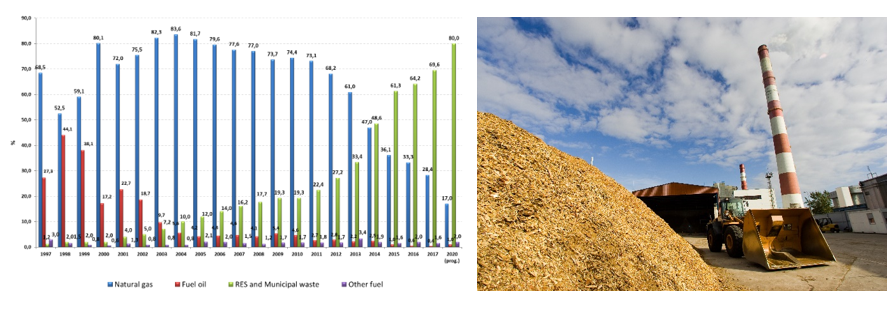

The peak in prices for natural gas in 2007-2012 and the EU’s policy of greater use of renewables have led to the rapid construction of biomass-fired boilers and cogeneration plants in Lithuania. The result of state aid and incentive regulation was that already in 2017 about 70% of the total district heat production was from renewable fuels – wood chips.

Fig 4. The structure of primary fuel in DH production 1997 – 2017

A considerable contribution here was made not only by heat suppliers, but also by independent heat producers who built about one third of the plants using biomass. Competition among heat producers is organised on the basis of monthly heat sale auctions. There is a national fuel and energy exchange in Lithuania, BALTPOOL, where all heat producers are required to buy fuel and sell heat in individual municipalities. The experience of the exchange attracts interest from foreign politicians and officials. BALTPOOL is extending its activities to other countries.

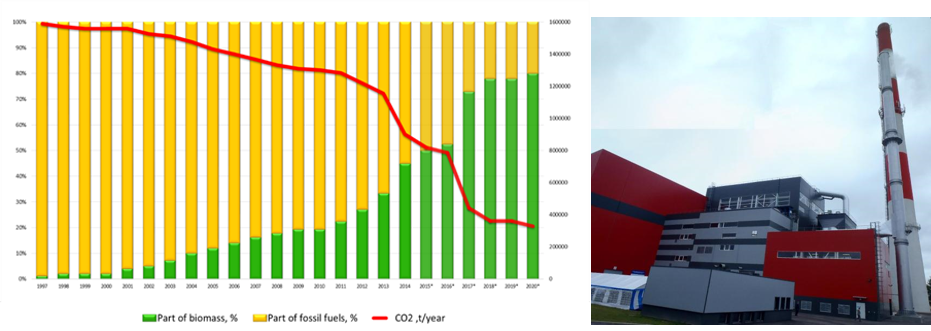

The replacement of fossil fuels – natural gas – with renewable biofuels has significantly reduced CO2 emissions.

Fig 5. Greenhouse gas (CO2) emissions in Lithuanian DH Sector

It was mainly on account of decarbonisation of the DH sector that Lithuania has long achieved the EU’s target of reducing carbon emissions by 20% by 2020. Additionally saved quantities of CO2 emissions are sold to other countries. The large share of renewable energy in the production of district heating means that this energy is suitable even for class A++ buildings. As biofuels are two to three times cheaper than natural gas and EU subsidies are used for equipment, heating prices have fallen significantly in recent years and district heating is increasingly appealing to heat consumers.

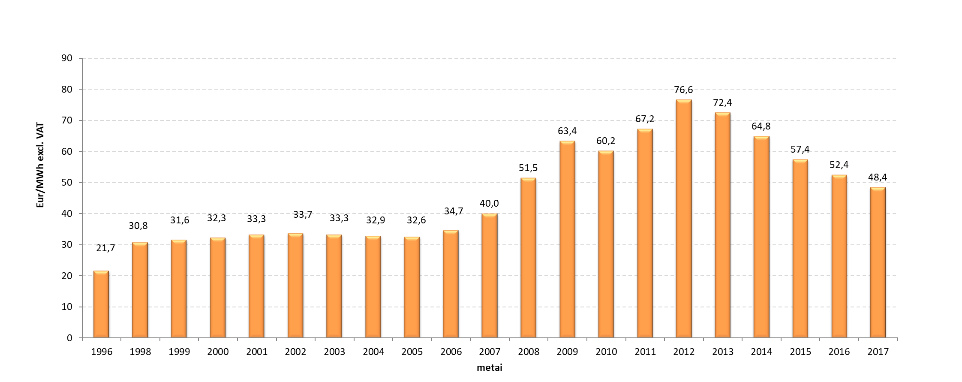

Fig 6. Average DH price in 1996-2018

Rapid replacement of imported natural gas with local renewable biomass is also of great benefit to the Lithuanian economy: new jobs are created, more funds and taxes remain in the country, regions are developing and new industries are growing. Today, Lithuanian manufacturers of boilers and other equipment sell their products and services not only in Eastern Europe, but also in Western European countries. Support for biofuel penetration in the Lithuanian DH sector is considered one of the best examples of the use of EU support.

Present and future challenges

In order to maximise the use of DH potential in the Lithuania’s energy sector, there are two high performance CHP plants under construction in Vilnius and Kaunas. Together with one of Fortum’s CHP plants already commissioned in Klaipėda, the three CHP plants will use non-recyclable waste generated in Lithuania and convert it into much-needed electricity and heat. In Vilnius, a biofuel-fired cogeneration power plant is under construction together with a waste incineration unit. With a total power generation capacity of 92 MW, the plant will efficiently produce 229 MW of heat, which will satisfy about 40% of the heat demand in the capital of Lithuania. These and other power plants will help Lithuania switch off from the Russian energy system and synchronise its power system with the continental EU’s power grid. This is the final step in Lithuania’s energy independence strategy.

The Lithuanian DH sector continues to implement new projects and reforms related to the adaptation to the accelerating renovation of buildings, broader use of ambient and waste energy, digitalisation of heat supply systems and further development and modernisation of DH systems. The country’s national goal is to produce heat with zero CO2 emissions by 2050, i.e. to produce heat from renewables only. Lithuania’s energy strategy is to promote the development of DH systems and cogeneration and to start district cooling of buildings through the use of financial support and incentive mechanisms.

The Lithuanian DH sector has accumulated many novelties which have won recognition and interest of foreign colleagues and experts. The experience gathered in the sector can be shared with others seeking to reduce environmental impacts and efficient district heating.

Latest News

-

-

26.10.2021 Celsius Summit 2021 – Energy Democracy

26.10.2021 Celsius Summit 2021 – Energy Democracy